Particularly heat sensitive items and instruments with complex, narrow lumen geometries require a careful and safe reprocessing that ensures a high material compatibility and effectiveness. The Formomat® PL with the LTSF (low temperature steam and formaldehyde) process according to DIN EN 14180 was developed specifically for the gentle processing of heat sensitive items and medical devices. The formaldehyde-based sterilization process meets all the relevant safety requirements.

Formomat PL-1

1

320 × 380 × 900

110

6,5

1,820 x 670 x 970

Formomat PL-2

2

320 × 380 × 900

110

6.5

1,820 x 670 x 990

Technical data subject to change without notice

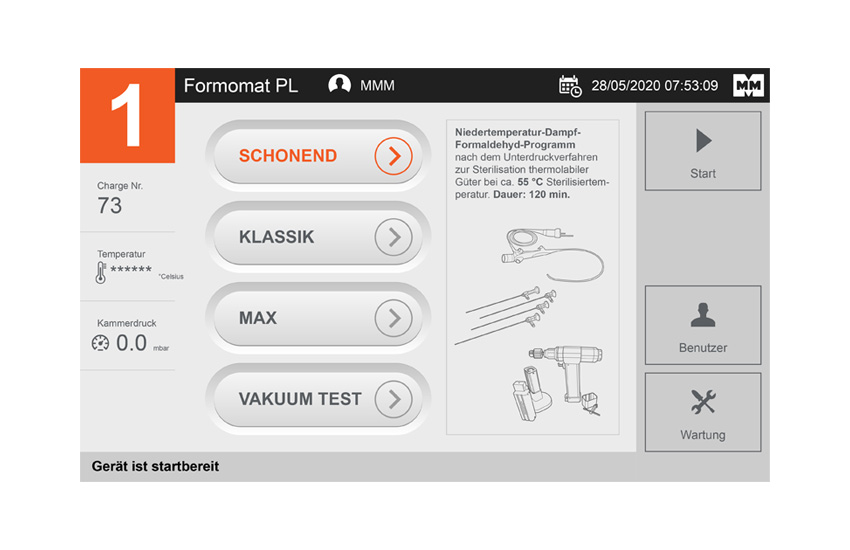

The Formomat® PL is characterized by its high quality, reliability, a user-friendly MMM smart HMI with touchscreen and, last but not least, its visual appearance. Three verified standard programs (55, 60, 75 °C) guarantee a gentle and safe sterilization process that is also highly efficient.

Exceptional performance matched with high cost effectiveness make the Formomat® PL an attractive machine for your RUMED. The Formomat® PL achieves a favorable total cost of ownership in all areas. The MMM LTSF sterilizer is not only well worth its (comparatively low) price, it also cuts down on operating and organizational costs. For instance, the costs of the agent (formaldehyde solution) and for replacement and wear and tear parts are very low. The ability to use commercially-available paper/film packaging material impacts very positively on the overall costs.

The human/machine interface (Smart HMI) is one part of MMM’s concept for simplifying the work of operating personnel. All process-relevant information—such as the device status, process steps, values, and process graphs—can be read at a glance on the display.

The high quality Formomat® PL combines unmatched technologies with a high level of safety and optimized user-friendliness. It was specially designed to sterilize heat sensitive medical devices with complex and narrow-lumen geometries.

Environmentally friendly

The low formaldehyde concentration of less than 0.2 g per liter in the condensate after the sterilization process reduces the impact on the environment and increases the operator safety.

Low temperature sterilization

The process maintains a minimum temperature of as low as 55 °C. This gentle method causes less heat stress to the materials of the medical device. All cycles are suitable for long and narrow lumens and comply with the requirements of DIN EN 14180. Standardized PTFE test device with a length of 1.5 m and inner diameter of 2 mm.

Safety for patients and operators

The Formomat® PL is especially user friendly. The main sterilizing agent is very safe, and operates with a low formaldehyde concentration of only 2% in a safe and closed chamber. Patient safety: The formaldehyde residues on the medical device after the sterilization process are significantly lower than the limit values specified in DIN EN 14180. This is achieved thanks to effective steam flushing and alternating venting and vacuum, additionally supported by an integrated fan. Safety for operators: The limit values for the protection of workers are below the values specified in Directive (EU) 2019/983. High process reliability: The continuous flow evaporator ensures an even distribution of the sterilizing agent within the chamber – regardless of the load. This enables even complex instruments with long lumens to be reliably sterilized.

Cycle time

The cycle time depends on the material from which the medical device to be sterilized is made. The Formomat® PL comes with three pre-configured cycles: GENTLE: 55 °C/120 min., CLASSIC: 60 °C/60 min. and MAX: 75 °C/30 min.

The modern industrial PLC control system offers many features and a high capacity. MMM also uses the same control systems in its steam sterilizers and washer-disinfectors for safe and user-friendly operation.

Trays and hoses

Rigid endoscopes and accessories

Flexible endoscopes and accessories

Electrical equipment

Download the brochure and find out more about the Formomat® PL

MMM Group

Semmelweisstraße 6

82152 Planegg/Munich

Germany

Costumer Service