In healthcare, they offer a flexible solution for responding to constantly changing requirements in the individual disciplines or mastering the current challenges in healthcare. For example, the Covid-19 challenges.

The medical equipment and furnishings can be supplied on request or provided by the building owner!

The example ICU shown operates fully autonomously. Besides the special feature that all units are equipped as single-bed rooms with a hygiene lock, the use of intelligent climate control technology also allows the intensive care treatment of either highly immune-suppressed patients in a positive pressure environment, or patients with aerogenically transmissible diseases in a negative pressure environment. This unit therefore ideally supports those having to manage the current Covid-19 challenges. The hygiene locks can optionally be designed as washrooms or toilets.

The medical equipment and furnishings can be supplied on request or provided by the building owner!

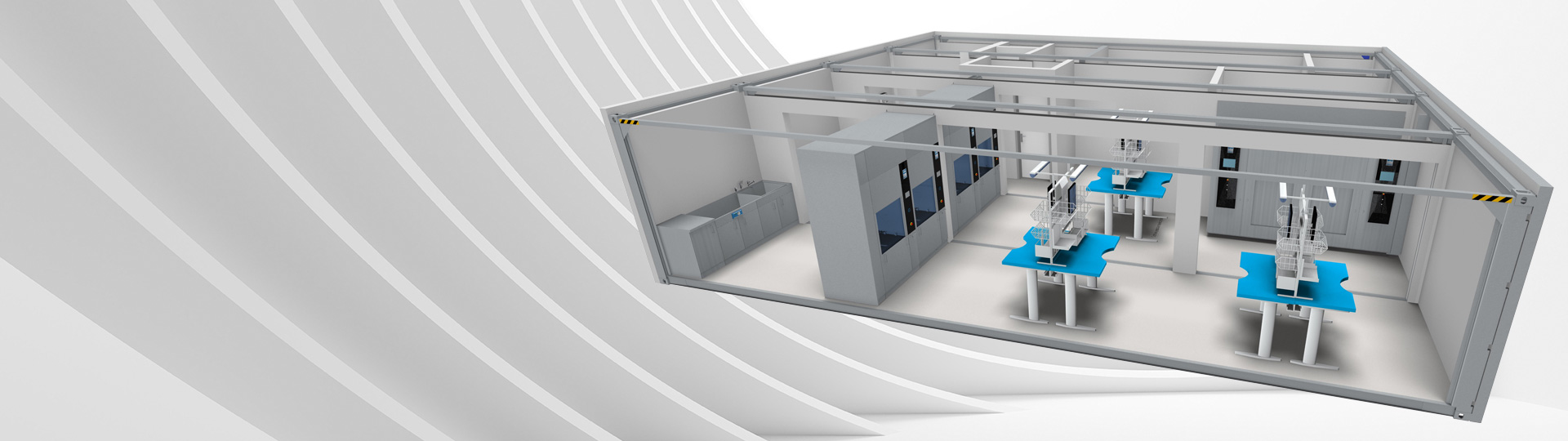

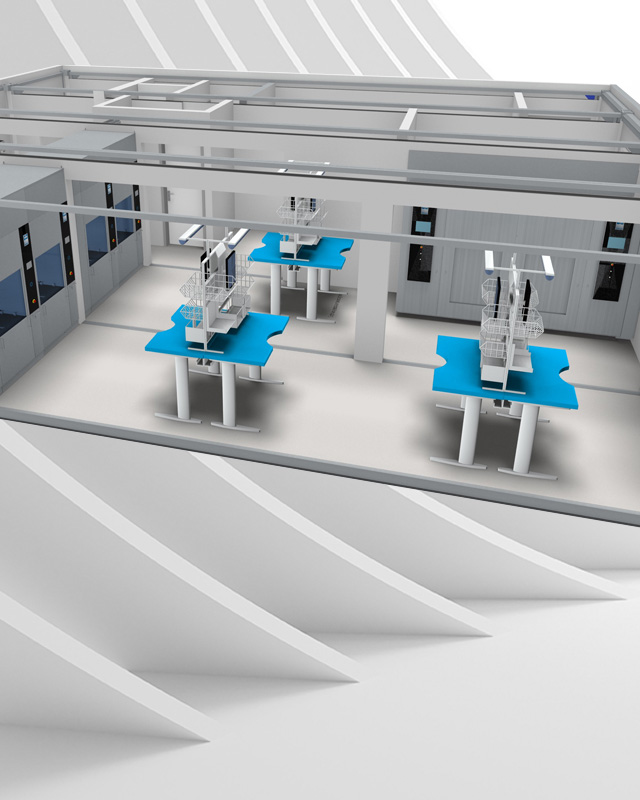

The example OR unit shown operates fully autonomously. The medical equipment and furnishings can be supplied on request or provided by the building owner! It is also optionally possible to extend the facility with further functional units for other disciplines, such as ICU or endoscopy units and normal wards.

The example endoscopy unit shown is currently in planning. This unit has also been designed to be fully autonomous and can be extended with appropriate technical equipment or further functional units for other disciplines. The medical equipment and furnishings can be supplied on request or provided by the building owner!

Phone: 089 899 18-0

Email: info-gu@mmmgroup.com

MMM Group

Semmelweisstraße 6

82152 Planegg/Munich

Germany

Costumer Service