The equipment options of the Vakulab® PL Compact Line are so wide-ranging and versatile that they cover a particularly broad field of application. The basic configuration of the sterilizer already satisfies all standard requirements for research laboratories, animal sciences, and industrial applications—both in terms of quality and the range of available chamber volumes.

636

670 x 360 x 700

160

2,400 x 960 x 990

666

702 x 652 x 690

314

2,400 x 995 x 990

669

702 x 652 x 990

453

2,400 x 995 x 1,290

6612

702 x 652 x 1,340

610

2,400 x 995 x 1,640

6618

702 x 652 x 1,940

883

2,400 x 995 x 2,240

Technical data subject to change without notice

The Vakulab® PL Compact Line complies with the Pressure Equipment Directive (PED) 2014/68/EU and the Machinery Directive 2006/42/EC. The sterilizer has been designed for sterilizing solid and porous materials, liquids in open or loosely sealed containers, and infectious waste. It bears the CE marking according to PED.

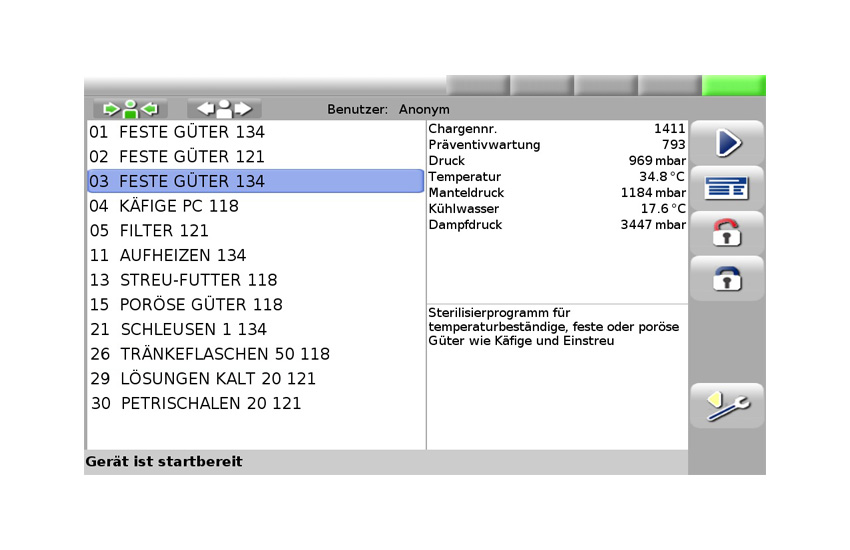

It has many standard features: maximum width of less than one meter, industrial PLC control system from B&R, smart HMI with 16:9 color touchscreen, vertical door movement, steam-operated door seals for optimal process reliability, separate steam supply to chamber and jacket, large selection of pre-configured standard programs, color-coded pipe insulation, polished chamber surface Ra 1.25 µm, LED chamber lighting, low noise and water saving two stage vacuum system, pneumatically driven steam valves. All pipes, fittings and valves that come into contact with process steam are manufactured from stainless steel. The standards applied are: DIN 58951-2 Steam sterilizers for laboratory use, AD 2000 Design of Pressure Vessels and DIN EN 62304 Medical device software.

High-tech – harnessed intelligently

The latest generation of PLC controllers enables intuitive operation, password-protected data management, and parameter-controlled free process programmability that allows all project-specific details to be individually accounted for.

Download the brochure and find out more about the Vakulab® PL Compact Line

MMM Group

Semmelweisstraße 6

82152 Planegg/Munich

Germany

Costumer Service